Mechanical Seals

Cartridge Seals

Single Rotary Cartridge Seal

- Single internal cartridge mounted rotary seal designed for general service applications

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 5000 f/m

Double Rotary Cartridge Seal

- Multiple cartridge mounted rotary seal designed to be easily adapted on equipment that is difficult to fit

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 5000 f/m

Unitized Single Cartridge Seal

- Single internal cartridge mounted stationary seal with restriction bushing for the utilization of a quench and drain for general service applications

- Pressure – 300 PSI

- Temperature – 400F

- Speeds – 10,000 f/m

Unitized Multiple Cartridge Seal

- Stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive lubrication without product dilution is required

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 10,000 f/m

High Temperature Metal Bellows Seal

- Component metal bellows seal using grafoil secondary seals to handle elevated temperatures without any adverse effects

- Pressure – 350 PSI

- Temperature – 700F

- Speeds – 4000 f/m

Low Temperature Cartridge Metal Bellows Seal

- Single non-pusher, rotating welded metal cartridge design

- Rugged design is great for handling the extremes of high temperatures

- Edge welded design has the flexibility to fit in ANSI and DIN standards as well as other pieces of equipment

- Manufactured to disperse the stresses on the welds

- Rotating bellows throw off suspended particles and provides the self cleaning effect which reduces the possibility of solids entering the bellow convolutions

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 4000 f/m

Split Seals

- Combination of a two piece rotary and a two piece gland/stationary

- Balanced design which allows for pressures put to 300 PSI

- Seal face wear indicator gives early warning for planned maintenance

- Pressure – 200 PSI

- Temperature – 250F

- Speeds – 2000 f/m

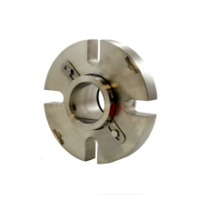

Balanced Single Spring Seal

- Rotary designed, balanced, single spring seal capable of handling higher operating pressures than conventional unbalanced single spring designs

- Large coil springs are resistant to clogging and allow the BSS to operate successfully in equipment with end play to 1/8″

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 1800 f/m

Cartridge Grease Seal

- Single, cartridge mounted mechanical seal that can be used to replace double seals without using a water flush

- Grease barrier cavity to prevent product leakage to the atmosphere without elaborate environmental controls

- Pressure – 350 PSI

- Temperature – 250F

- Speeds – 10,000 f/m

Hot Oil Seal

- Balanced single spring rotary seal capable of handling conditions much higher than conventional single spring designs

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 5000 f/m

Externally Set Double Seal

- Back to back multiple seal designed for application where positive lubrication is required from an external flush without dilution of product

- Since all metal parts are isolated and the pumped product is sealed from the stuffing box, the ESD is an economic solution to sealing extremely corrosive and abrasive fluids

- Pressure – 75 PSI

- Temperature – 250F

- Speeds – 5000 f/m

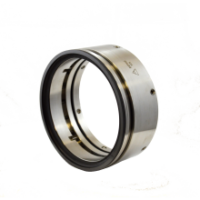

High Temperature Cartridge Metal Bellows Seal

- Cartridge metal bellows seal using grafoil secondary seals to handle elevated temperatures without any adverse effects

- Pressure – 350 PSI

- Temperature – 700F

- Speeds – 4000 f/m

Reciprocal Balance Duplex Seal

- Stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerate and where positive lubrication without product dilution is required

- Pressure- 350 PSI

- Temperature – 400F

- Speeds – 10,000 f/m

Vertical Single Rotary Seal

- Single, external cartridge mounted rotary seal design for installations where shaft deflection exceeds the limits allowed by off-the-shelf cartridge seals

- Pressure – 350 PSI

- Temperature – 400F

- Speeds – 5000 f/m

Reviews

There are no reviews yet.