Metallic Gaskets

Jacketed

Design

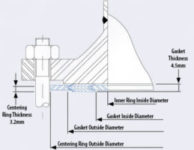

- Gaskets confined by the inside and outside diameters

- Gaskets inside diameter = groove inside diameter plus 1/16″

- Gaskets outside diameter – groove outside diameter less 1/16″

- Gaskets confined by outside diameter

- Gaskets inside diameter = flange inside diameter plus a minimum of 1/8″

- Gaskets outside diameter – groove outside diameter less 1/16″

- Non confined gasket

- Gaskets inside diameter = flange inside diameter plug 1/8″

- Gaskets outside diameter = bolt circle diameter less bolt diameter

Style 923/927

- Flat double jacket gasket typically used in heat exchangers or large size reactors in chemical plants

- Compensates for distortions and irregularities of flanges

- Style 927 is similar to 923 with the addition of flexible graphite facing

- Thickness of 5/32″ to 1/4″

Style 920

- Round single jacket gasket typically used where the seating stress and width are limited

- Can be manufactured in circular or oval shape

- Maximum width is 1/4″ and standard thickness is 3/32″

Style 926

- Similar to 923 but the metallic jacket is corrugated

- The corrugations act as a labyrinth

Style 929

- Similar to 926 with the corrugated metallic filler

- Used in applications where it is necessary to have a gasket without non-metallic materials, temperature limits and chemical resistance

SKU: 1761

Category: Metallic Gaskets

Reviews

There are no reviews yet.