Metallic Gaskets

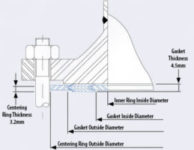

Ring Joint

- Typical applications is the “Christmas Tree” in oil fields

- The seal is obtained in a line of contact by a wedge action with high seating pressures, thus forcing the gasket material to flow

- The small sealing area with high contact pressure results in great reliability

RJ Materials

Soft Iron – 56 Hardness

Carbon Steel – 68 Hardness

AISI 502 – 72 Hardness

AISI 410 – 86 Hardness

AISI 304 – 83 Hardness

AISI 316 – 83 Hardness

AISI 347 – 83 Hardness

Monel – 70 Hardness

Inconel 625 – 68 Hardness

F11 – 68 Hardness

Style 950

- Frequently referred to as oval ring

Style 951

- Octagonal section

- Better sealing performance than Style 950

- Recommended for new applications

Style 952 BX

- Square cross section with bevelled corners

- Designed for use only in flanges API 6BX

- Recommend for pressures from 5000 PSI to 20000 PSI

Style 953 RX

- Pressure activated gasket

- Shape is designed to use the fluid pressure to increase the sealability

- The outside sealing surface of the gasket makes the initial contact with the flange seating the gasket

- As internal pressure of the piping or equipment is increased, the contact pressure between the gasket and flanges also increase due to the shape of the gasket

- Resistant to vibrations, pressure surges and shocks that occur during oil well drilling

- RX is interchangeable with style 950 and 951, using the same flange grooving

SKU: 1763

Category: Metallic Gaskets

Reviews

There are no reviews yet.